| |

المؤلفون / Authors

الملخص / Abstract

الكلمات المفتاحية / Keywords

أقسام الملف

Introduction

Fire extinguishing systems

Choosing the most appropriate extinguishing system Heptafluoropropane

Gas System (FM200)

Design of fire extinguishing systems

Calculations for the FM 200 gas extinguishing system

Design of firefighting systems in the study sample

The results of the study

Proposals

Futureprospects

References

|

| Design of an automatic fire extinguishing system in a local operations department |

| |

| Dr. Alaa Rahhal [1] Dr. Hanan Mukhaiber [2] |

| Al-Andalus University for Medical Sciences |

| Damascus University. |

| mjmrahhal@gmail.com hmukhaiber@yahoo.co.uk |

| |

| |

|

| |

|

| [1] lecturer at the Faculty of Medical Engineering - Al-Andalus University for Medical Sciences |

|

| [2] Assistant Professor at the Faculty of Mechanical and Electrical Engineering - Department of Medical Engineering - Damascus University |

|

|

Abstract:

Research Background and Objective: Fire is one of the serious disasters that hospitals may be exposed to, as it usually starts on a small scale, but quickly spreads if it is not controlled quickly, leaving huge losses in lives, money, and others. Operations suites are among the most sensitive and dangerous departments of the hospital in the event of a fire, as they deal with critical cases of unconscious patients undergoing surgery, in addition to being an economically costly environment rich in fire causes.

This research aims to study the current reality of the firefighting system in the operations wing of a local hospital (Al-Basil Hospital in AL-Qardaha) in order to identify problems and gaps that are useful in formulating appropriate solutions that will increase the security and safety of patients and staff in addition to the existing equipment.

Research materials and methods: The research was based on the inductive approach, which starts from the private level (local hospitals) and the study of their condition in order to collect data and information about them in order to accurately describe their current situation. Then the research employed the method of comparative analysis in order to compare the results of the inductive approach (the current state of the studied hospital) with international standards and then find the optimal design for the fire extinguishing system in the studied section.

Results: The study reached a thorough study of the current reality of the firefighting system and the design of an automatic firefighting system for the entire section in addition to a manual firefighting system in less dangerous places to reduce the design cost.

Conclusion: The trampled fire extinguishing system in the research is a highly effective safe system that ensures the safety of the patient and the medical staff surrounding him in the event of a fire during the course of the surgical work.

|

|

| Keywords: fire, extinguishing, FM 200, operating rooms. |

|

| 1. Introduction: |

|

|

The danger of fires in operating rooms is exacerbated by the abundance of the three elements that make up the ignition triangle: heat, fuel and oxygen. Practically, these rooms contain many sources of fire hazard (anesthesia devices, electric scalpels, electrical circuits, a network of medical gases and compressed air, ... etc., in addition to the availability of elements that assist in the spread of fire such as doors, windows, air ducts ... etc., which help The flame spreads quickly [1].In several documented cases, the fire starts from the patient in the operating rooms and then moves to the devices connected to it (anesthesia, cardiac monitoring...etc.) [3][2].The estimated number of surgical fires is ( surgical fires) that occur annually in the United States of America with 550-650 accidents, a number of these accidents cause serious injuries to patients, disfigurement, and even death. Therefore, the study of the alarm system in addition to the fire extinguishing process in operating suites receives great attention due to its role in preventing the spread of Fire when it occurs by providing appropriate warning and effective suppression mechanisms [4]. Proper planning and design of surgical suites is one of the main factors to ensure the provision of appropriate medical care to patients (success of surgical work associated with improvement of patients’ condition) on the one hand, in addition to contributing to the M and implementation of effective fire alarm and firefighting systems on the other hand.

Surgical fire has received the attention of many researchers and many studies have been conducted in this context, including PhD research carried out in 2016 AD in the field of nursing practice under the title “Surgical Fire Safety in an Urban Surgical Center”, at Georgetown University, Washington [4]. The aim of this the research is to improve knowledge and awareness of the importance of surgical fire risks, and to increase practitioners' use of the fire risk assessment tool while preparing reports related to surgical safety, given the large number of surgical fires that occur in America, which ranges between 200 and 240 surgical fires annually.

An educational intervention on the underlying causes of surgical fires and risk assessment was designed based on published evidence and findings from a survey of knowledge, attitudes and practices. The target sample was all members of the surgical staff at the center under study. In order to assess the amount of benefit from this educational intervention as well as the current and desired practices, 10 items were selected from the intervention and a test was conducted for the study sample before and after the application of the intervention, with this test being repeated after three months (a follow-up test) to assess the extent of retention of the knowledge provided during the educational intervention and the amount of change actual occurrence in practice. The analysis of the test answers was done using descriptive statistics.

The average correct percentage of the test before the educational intervention was 48.82%, while its value increased to 71.88% immediately after the intervention, to fall after the three months to 58.57%. 93% of participants in the follow-up test indicated that they incorporated surgical fire prevention strategies into their practice, compared to 82% in the pre-intervention test. In the pre-intervention test, no question was asked specifically related to the use of fire risk assessment, although 50% of participants reported using fire risk assessment during the preparation of postoperative surgical safety communications.

The researcher concluded that the implementation of a brief educational intervention on surgical fires contributes to raising awareness among workers in operating departments of the dangers of surgical fire, its causes and how to avoid it, and highlights the need to follow prevention strategies. With an emphasis on the role of government institutions in emphasizing the application of fire risk prevention measures within health care facilities in general and within operations departments in particular.

Another study is a master's thesis in public health from the University of Toronto, Canada titled "Safe Surveillance of Medical Devices Related to Surgical Fires". [5] The aim of this research is to identify and analyze reports of surgical fires related to medical devices in support of the Prevention of Surgical Fires (PSF[1]) initiative.

The researcher searched for surgical fires related to medical devices that were officially reported between the years 2008-2009 within the database of the Food and Drug Administration (FDA[2]) related to medical device accidents. This is in medical device reports compulsorily submitted by medical device manufacturers and importers and the facilities that use them as well as voluntarily reported reports by healthcare professionals, patients and consumers (MAUDE[3]).

|

|

| After identifying the relevant reports, they were analyzed and classified statistically according to the cause of surgical fires in addition to their severity. The researcher reached the following results: |

|

| 1-. The total number of surgical fire reports submitted to the FDA in 2008 was 65, and the number of reports for 2009 was 47 (excluding reports from foreign sources, these reports total 48 and 39, respectively). |

|

| 2-Oxygen contributed to 29% of the total reports of surgical fires for the year 2008, and to 3% of the cases in 2009. While alcohol-based substances that are used to prepare the patient's skin for surgery contributed to 4% of the 2008 reports and 11% of the cases. 2009 reports. |

|

| 3-Burning cases were reported in 35% of 2008 cases and 52% of 2009 cases. Surgical fires that did not result in any human injury were 35% and 38% of 2008 and 2009 cases, respectively. |

|

| 4-The results of surgical fires were unknown in 22% of the 2008 reports, and in 2% of the 2009 reports. While one death incident was reported in 2008, and also in 2009. |

|

| 5-After comparing these findings with estimates in relevant research, it is likely that officially reported reports of surgical fires involving medical devices underestimate what actually occurs on the ground (largely due to underreporting). Therefore, it is necessary to take the necessary measures to activate the reporting of actual surgical fire incidents as an important step in studying them, evaluating their risks, and adopting best practices to reduce their risk. |

|

| 2. Fire extinguishing systems: |

|

| Firefighting methods are based on controlling the three elements of the fire triangle. If oxygen is withheld, the temperature of the substance is reduced, or the amount of burning materials is reduced, then the fire can be extinguished. These methods include: cooling, blocking, dormancy, disrupting the chemical reaction, starvation [6]. |

|

| Fire extinguishing systems are divided into two main parts: |

|

| - Manual extinguishing systems: These are the systems that are installed in the sites to be protected from the dangers of fire and are operated by one or more people, and the benefit is realized if they are found in sufficient numbers and with appropriate extinguishing capabilities for the site, as well as with the presence of individuals trained to use them [6]. |

|

| - Automatic extinguishing systems: They are fixed systems that operate on their own after detecting a fire, by distributing suitable quantities of fire extinguishing materials within a short period of time to extinguish the fire immediately upon its outbreak, and are specially installed to protect the space, location, or device to be protected. The extinguishing agent inside the system has been selected to fit the protected space. |

|

| One of the advantages of these systems in extinguishing fire is that they detect the presence of fire, and intervene automatically and immediately without the need for the intervention of individuals. One of the disadvantages of these systems is that they are expensive and require costly periodic maintenance. Therefore, it is used to protect sensitive and expensive devices. These systems are divided into [1]: |

|

| *Automatic sprinkler systems (wet system, dry system, delayed system, total immersion system). |

|

| *Clean gas systems (Halon system, Inergen system, Heptafluoropropan gas system, CO2 system, etc.). |

|

| 3. Choosing the most appropriate extinguishing system: |

|

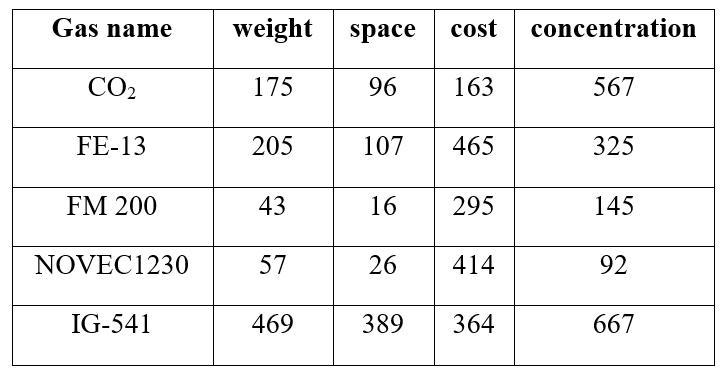

| From the foregoing, any gas can be used to extinguish a fire, so a comparison was made between the five gases to identify the best gas, with halon gas being the reference gas for this comparison (see Table 1). Where each variable of halon gas was given a value equal to (100%) and then the value of each variable was calculated for each gas compared to the value (100%) of halon gas. The reason for using halon gas as a reference is that it is the best in extinguishing fires and is no longer in use, and thus it is a neutral reference compared to other types of gases. The following variables were taken into consideration: |

|

| *Weight: the ratio of the weight of the equivalent gas required to protect the same space to the weight of halon gas, where the ratio (175%) means that the value of the variable for gas is higher than that of halon gas by (75%), and the ratio (96%) means that the value of the variable is less than that of halon gas Halon by (4%). |

|

| *Area: The ratio of the area of the space required for the installation of gas cylinders to the space required for halon gas cylinders needed to protect the same space |

|

| *Cost: the ratio of the cost of the amount of gas needed to protect the space to the cost of the amount of halon gas needed to protect the same space. |

|

| *Concentration: the ratio of the gas concentration needed for the space to the concentration of halon gas needed to protect the same space. |

|

| Table (1): Comparison of some of the properties of clean gases with the adoption of the reference to be halon gas.[1] |

|

|

|

| We note from the previous table that the cheapest gas for use is CO2 and the best safety for humans in the space is NOVEC 1230, while the lowest amount of gas needed for extinguishing is found at FM 200 and therefore requires the least space to place gas cylinders. |

|

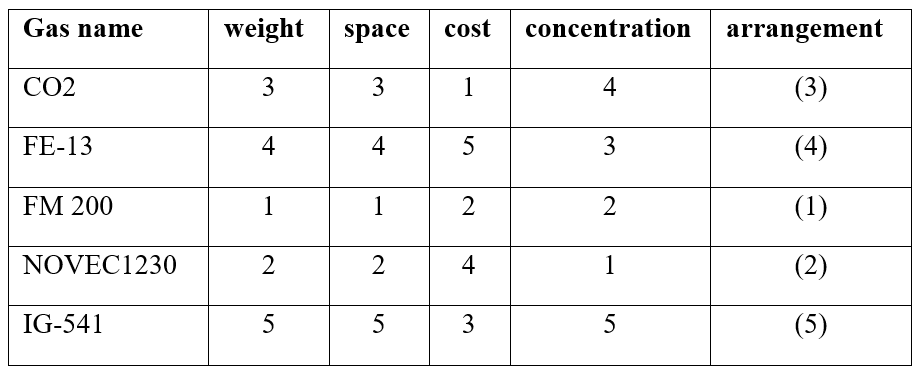

| In order to clarify this differentiation between the five gases, they are arranged in Table (2) in order of preference. Number (1) is the best gas for the variable, and number (5) is the worst. We calculated a median arrangement, giving each variable a specific weight, where cost and safety were given a higher weight than the other variables, and we found that the arrangement of gases is as shown in the last column of the table. It should be noted here that this intermediate arrangement depends on the importance given to each variable. |

|

| |

|

| Table (2): Order of preference for the properties of extinguishing gases [1] |

|

|

|

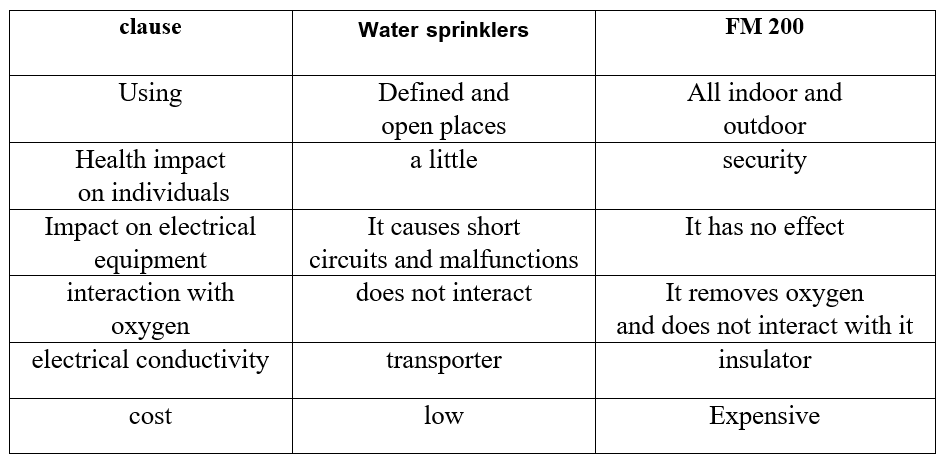

| We note from the previous table that the best clean gas for extinguishing when taking into account all specifications is FM 200. Therefore, a comparison was made between the FM 200 fire extinguishing system and the water sprinkler system, as shown in Table (3). |

|

| Table (3): Comparison of types of automatic fire extinguishing systems. |

|

|

|

|

It is clear from the previous discussion that the FM200 extinguishing system is superior to other extinguishing systems despite its large cost (which may reach up to 8000-10000 US dollars for an area of 50 square meters), so it was relied upon in our research during the design of automatic extinguishing systems within the operating suites.

|

|

| 4. Heptafluoropropane Gas System (FM200) |

|

| It is a clean, colorless and odorless gas. It does not leave a trace after extinguishing the fire. It is also non-conducting electric current and is non-toxic. It does not negatively affect the respiratory system if its concentration in the room is less than (9%). It is a gas consisting of carbon, hydrogen and fluorine, with a chemical formula (CF3CHFCF3) and is scientifically known as (HFC-227ea) and the common name is FM200. |

|

| It is currently widely used instead of halon, but it is more expensive and requires a larger number of gas cylinders to combat the same space. |

|

| It is distinguished, if used at an appropriate concentration, by being effective in extinguishing the fire, as it interacts with the burning material, stops chemical reactions, and also blocks oxygen and does not interact with it, so it does not affect the amount of oxygen in the room and cools the burning material and absorbs its heat [1]. |

|

| Although many scientific references allow the installation of a traditional water-based extinguishing system in operating rooms, it is not the best solution, due to its specificity and the nature of work in it, and water will cause great damage to existing devices and equipment, so the best option would be to use clean gases, especially gas Extinguishing (FM 200), as it absorbs heat until it drops below the flammable range, with a slight displacement in the proportion of oxygen present in the space. We can summarize the advantages of FM-200 gas fire extinguishing systems as follows: |

|

| -Detecting and extinguishing fires in their early stages to prevent damage and disruption of work. |

|

| -A security system that does not harm people in the fire area, as they can breathe within predetermined design concentrations. |

|

| -It does not affect the electrical equipment and fixtures in the firefighting site. |

|

| -No need to clean after using it, because it leaves no residue or traces. |

|

| -No danger after extinguishing the fire. The FM-200's only impact on the environment is a slight drop in temperature. |

|

| There are three common designs for the FM200 extinguishing system as follows: |

|

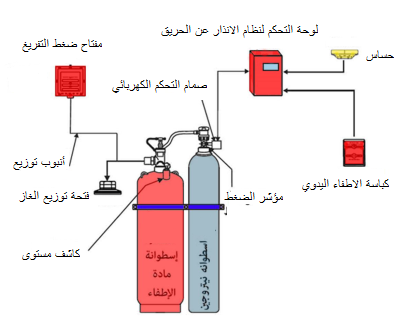

| The first design: the gas is packed in special steel cylinders with a density not exceeding (285) kilograms per cubic meter. It is distributed in the protected space through a network of tubes and a set of sprays. The operation of the system is controlled by electrical and mechanical electronic control devices. Illuminated warning and indicative panels are placed at the entrances to the protected space, as in Figure (1). |

|

|

|

| Figure (1): The first design of the FM200 gas extinguishing system [25]. |

|

| The second design: a design in which the FM200 cylinder is pressurized with nitrogen under natural conditions, and the extinguishing is done by opening the FM200 valve to let the gas out under the influence of nitrogen pressure. This valve has both manual and electric opening properties, as shown in Figure (2). |

|

|

|

| Figure (2): The second design of the FM 200 gas extinguishing system [25] |

|

| The third design: a more complex design than the previous two designs, in which there are two nitrogen cylinders, one of which is small, and it is opened by means of an electrical signal from the system, so that the pressure coming out of it opens the main nitrogen cylinder, and perhaps more than one cylinder, which in turn presses the FM200 cylinders to start the extinguishing, as in Figure (3). |

|

.png) |

|

| Figure (3): The third design of the FM 200 gas extinguishing system [25] |

|

| All cylinder gases must be discharged into the protected space very quickly, not exceeding ten seconds. The concentration of gas in the room must not be less than 7%, or about half a kilogram of gas per cubic meter of space. The system is designed at temperatures not less than (21) degrees Celsius and not more than (55). [6] |

|

| 5- Design of fire extinguishing systems: |

|

| After the justifications for choosing the appropriate extinguishing system for our research (FM200 system) have been clarified, we will now explain its special requirements and related calculations. Note that the calculations were based on the following National Fire Protection Association (NFPA) standards: |

|

| - No. 2001 Clean Agent Fire Extinguishing Systems. |

|

| - No. 70 National Electric Code. |

|

| - No. 72 National Fire Alarm Code. |

|

| There are two ways to implement one of the three designs of the gas extinguishing system according to the NFPA standard: The first is used when there are more than one room next to each other, and the calculation is based on the largest room. |

|

| One location is chosen for the location of the cylinder group, and it must be close to all space voids in order to avoid the pressure drop resulting from the walls of the pipes along the path leading to the spray nozzles, and away from damp places and external weather factors, and it is preferable that it be spacious in order to facilitate installation operations and the following operation and maintenance [1]. |

|

| As for the pipes, they are distributed within the adjacent rooms, with a check valve for each line for each room, noting that this design has the following features: |

|

| *Less expensive compared to the second design. |

|

| *Fewer cylinders and smaller space compared to the second design. |

|

| *One of its problems is that it is ineffective in the event of a fire breaking out in more than one room. |

|

| The second design of the gas extinguishing system was found to solve the problem in the previous design by designing an independent extinguishing system for each room. Each room is provided with gas cylinders commensurate with its size, and this system has the following advantages: |

|

| *Greater economic cost compared to the first design. |

|

| *It needs more cylinders and more space compared to the first design. |

|

| *Effective in the event of a fire breaking out in more than one room at the same time. |

|

|

In our research, the first method was relied upon in the design, due to its advantages, especially the lower economic cost and the smaller space for placing the cylinders.

|

|

| 6. Calculations for the FM 200 gas extinguishing system |

|

| The code (NFPA 2001) was followed to obtain the calculations for the FM 200 gas extinguishing system adopted in our study. In the following, we will mention the details of the mathematical equations used, and the calculations are carried out according to the following stages: [7] |

|

| 6-1 Risk analysis to determine the required gas percentage: |

|

| Hazard analysis is the first and one of the most important principles in designing the FM-200 gas extinguishing system. Analysis information should include environmental conditions, personnel considerations, system operation under normal and unloaded conditions, construction, dimensions, volumes, and any special requirements. |

|

| The minimum design concentration for Class A and C fires is 7.17%. For the determination of the recommended design concentration for Class B flammable liquids, reference is made to the methodology approved in NFPA 2001. |

|

| All design concentration calculations are based on a safety factor of 20% for Type A and C and a safety factor of 30% for Type B. |

|

| 6-2 Calculating the weight of the gas required for extinguishing: |

|

| The size of the space is initially calculated by multiplying its three dimensions (length, width, height), where the full height of the ceiling is taken, including the false ceiling if it exists, and in the event that the space has an irregular geometric shape, it is rounded to the nearest defined shape (cube, Cuboid, sphere.... etc.). |

|

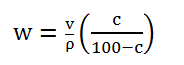

| The weight of the gas depends on the volume of the space at the minimum expected temperature and the required concentration. To determine the minimum gas weight the following equation is used: |

|

|

|

| Where |

|

| W: the weight of the clean medium (kg). |

|

| V: the net volume of the hazardous area (m3), |

|

| calculated as the total volume minus the volume of fixed structures that are impermeable to the vapor of the clean medium. |

|

| ρ: specific volume of vapor of the clean medium at a given temperature (kg/m3). It is calculated from the relationship: |

|

| ρ= 0.1269 + 0.0005131 t |

|

| t = design temperature in the danger zone (°C) |

|

| C: design concentration of the clean medium (% by volume) at temperature t. |

|

| The amount of gas can be calculated by knowing the immersion coefficient, G, at a certain temperature, using tables for the FM 200 extinguishing system, through the equation: |

|

| W=V×G |

|

| 6-3 Determine the number of cylinders: |

|

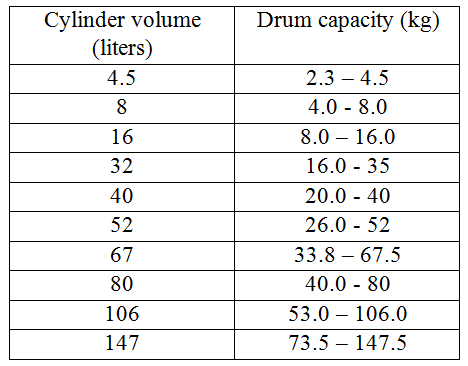

| There are many weights for FM 200 gas cylinders, depending on the request, or according to the design. Therefore, in specifying the extinguishing item with Fm 200, the designer decides how many kilos of gas the place needs, not how many cylinders. The following table (4) shows the capacity of the cylinders. |

|

| Table (4): Standard cylinder size and capacity |

|

|

|

| The number of cylinders is calculated by the relationship: |

|

| N=W/X |

|

| Where: |

|

| N: the number of cylinders, |

|

| W: the weight of the gas required, |

|

| and X: the capacity of the cylinder to be used. |

|

| 6-4 Determine the pressure required to empty the cylinders into the compartment: |

|

| FM 200 gas flows at low pressures from 12 to 133 bar, so compressed nitrogen gas is used with it to raise the cylinder pressure to 25 bar, and sometimes a nitrogen cylinder is next to it. |

|

| 6- 5 Determination of pipe diameters: |

|

| The gas consisting of a mixture of liquid and vapor flows in the designed network of pipes, and during this flow it will rub against its inner walls, which reduces its density and thus a non-linear pressure decrease and an increase in the flow velocity. If the piping diameter is too large for the design flow rate to result in alternate discharges of liquid and vapor, the diameter must therefore be properly fitted to keep the gas flow sufficiently turbulent to prevent phase separation. Most designs use pipes for the main line with a diameter of (1.5-2) inches, equivalent to (3.81-5.08) cm, and for branches with a diameter of (0.5-1) inches, equivalent to (1.27-2.54) cm. |

|

| 6-6 Determine the number of spray nozzles: |

|

| The number of nozzles required depends on the size of the space and the nature of the coverage provided by the nozzle. This number increases with the increase in the area or height of the space. Nozzles are available in 7-port or 8-port versions to provide 180 or 360-degree discharge patterns respectively as shown in Figure 4: |

|

.png) |

|

| Figure (4): Installation of spray nozzles [30]. |

|

| The following factors should be taken into consideration when considering the optimal orifice location: |

|

| -The location of the crater is affected by the shape of the danger zone. |

|

| -The maximum discharge diameter is 8.7m for a 360° nozzle and 10.05m for a 180° nozzle. |

|

| -The maximum coverage area for any of the nozzles is 95.3 square meters, and this area decreases when the discharge speed and ceiling height increase. |

|

| -The nozzle must not be positioned where it can pour into nearby objects. |

|

| -Nozzles must be installed a maximum of 30 cm below the ceiling. |

|

| -The maximum protection height with 360° and 180° nozzle is 4.87m. |

|

|

-The maximum distance between the nozzles is 9.1 m.

|

|

| 7. Design of firefighting systems in the study sample: |

|

| The Department of General Operations at Al-Basil Hospital in Al-Qardaha was selected as a study sample, and the design was built according to the following axes. |

|

| 7-1 Studying the department’s spaces and architectural plans: |

|

| The department consists of four operating rooms in addition to the sterile and dirty corridors, the recovery room, and the sterilization department. The following figures show the architectural plans for the department’s spaces and their classifications. |

|

.png) |

|

| Figure (5): Scheme of functional spaces for the operations department at Al-Basil Hospital in Al-Qardaha. |

|

.png) |

|

| Figure (6): Dimensional chart |

|

.jpg) |

|

| Figure (7): Diagram of sterility areas |

|

.jpg) |

|

| Figure (8): Corridor plan |

|

.jpg) |

|

| |

|

| Figure (9): Patient movement axis |

|

.jpg) |

|

| Figure (10): Axis of movement of surgeons |

|

.jpg) |

|

| Figure (11): Diagram of medical gas intakes and ventilation openings |

|

| 7-2- Studying the current reality of the existing firefighting system |

|

| There is no fire extinguishing system in the Operations Department of Al-Basil Hospital in Al-Qardaha, and the approved extinguishing mechanism depends only on the presence of one fire extinguisher (9-liter capacity containing dry powder) placed at the entrance of the department. Extinguishing materials are replaced annually. |

|

| Due to the absence of automatic fire-fighting systems, these systems were designed within the operating and recovery rooms. As for the rest of the departments’ spaces, manual extinguishing systems were adopted. This is due to the following reasons: |

|

| -The small number of fires recorded globally in operating departments outside the operating rooms due to the lack of the elements of the ignition triangle in them. In addition to the absence of patients and a large number of personnel or overcrowding of devices and equipment compared to operating rooms. Therefore, it is not economically feasible to install an automatic extinguishing system in them as long as the presence of manual extinguishers achieves the required protection and reduces the material cost at the same time. |

|

| -Difficulty using automatic systems in corridors and open spaces. |

|

| 7-3- Design of the fire extinguishing system in operating and recovery rooms: |

|

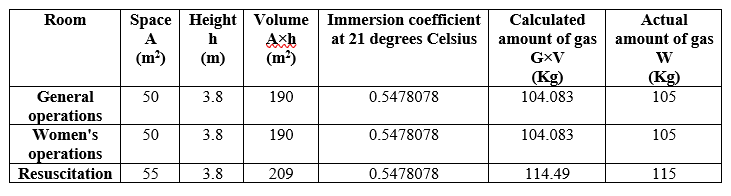

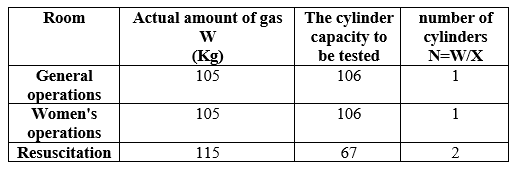

| The automatic extinguishing system using FM 200 gas was approved for the reasons mentioned above. We used one gas collector for each two adjacent rooms, and one collector for recovery. The collector was placed in the dirty corridor for ease of maintenance and the presence of large areas so that it does not cause any obstruction to movement. The amount of gas required for extinguishing was calculated based on the size of the room and its temperature (21 degrees Celsius) and the average Extinguishing within ten seconds with a gas concentration of 7%[1]. The immersion coefficient used in all calculations is (0.5478078[2]). Table (8.1) shows the amount of gas required for each protected room, which is calculated by means of the equation: |

|

| W=V×G |

|

| Table (5): The amount of gas required for each protected room of the Operations Department of Al-Basil Hospital in Al-Qardaha. |

|

|

|

| Depending on the amount of gas required for extinguishing, the size of the cylinders can be chosen. The appropriate option for operating rooms according to Table (4) is the cylinders with a capacity of (106 liters), while the resuscitation department needs cylinders with a larger capacity (147 liters). |

|

| As for the number of cylinders required for the design, it is shown in the following table (6). |

|

| Table (6): The number of cylinders required for the design in the Operations Department of Al-Basil Hospital in Al-Qardaha. |

|

|

|

| |

|

| We note from the previous table (8.2) that the resuscitation department can be covered with one gas cylinder with a capacity of (147 liters), but it causes waste of a good amount of gas (about 32 kg), because the extinguishing system completely empties the cylinder during emptying, so we used the capacity (67) So that two cylinders are connected in the accumulator to achieve the same effect and with less wastage of extinguishing gas (19 kg). |

|

| The gas pressure in the cylinders is 12 bar [30], so each FM 200 cylinder will be equipped with a compressed nitrogen cylinder to raise the pressure during the gas discharge to 25 bar (the pressure that secures the complete emptying of the gas within ten seconds) in addition to another nitrogen cylinder in order to activate the system properly Automatic as mentioned in the third design of the extinguishing system, see Figure (3). |

|

| The area of coverage of one spray nozzle is in the range of 16-20 square meters, and considering that the area of most operating rooms in the department is 50 square meters, the number of nozzles required to cover the space is: |

|

| 50/16= 3.125 |

|

| We note that three nozzles are sufficient to cover the space, but four nozzles were used in our design in order to match the pressure and speed in discharging the gas and extinguishing the fire, and since the height of the ceiling is more than 3.5 m, the nozzles must be installed on two different levels (two nozzles in the ceiling and two nozzles in the walls) Nozzles (180 degrees) were used because there are no false ceilings, as we will use nozzles (360 degrees) if there are such ceilings in order to discharge the gas above and below the ceiling, thus reducing the number of spray nozzles. |

|

| Pipes of black steel or galvanized steel are used in the system, and in order to maintain the pressure that achieves discharge during the specified period of design, the flow must be known in order to determine the diameters of the pipes required for the design. |

|

| The flow required to fill the operating room (area of 50 m2) with extinguishing gas is calculated as follows: |

|

| *The amount of gas required for extinguishing = 106 kg. |

|

| *Discharging time = 10 sec. |

|

| *Flow = amount of gas / discharge time |

|

| 10610 = 10.6 kg/sec |

|

| *Number of spray nozzles = 4 nozzles. |

|

| *Each orifice must discharge a quantity of gas with a flow of 10.6 / 4 = 2.65 kg/sec. |

|

| Based on the special tables, pipes of two different diameters will be used, 2 inches (5.08 cm) for the main feed pipe and 1 inch (2.54 cm) for the connections of the discharge nozzles [7] [8]. |

|

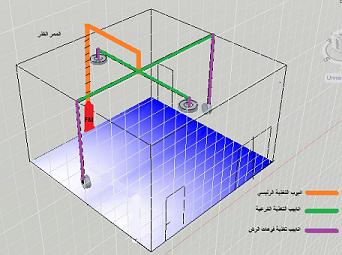

| Figure (12): shows an illustration of this design: |

|

|

|

| Figure (12): Method of designing the automatic extinguishing system [Researcher] |

|

| The system depends on its operation on a control panel that is installed in the dirty corridor, and it sends (in the event of a fire) stop orders to the air-conditioning units of the operating rooms, and it is connected to the detectors (thermal-flame) located in the ceiling of the room, so that it does not give an order to operate the system Unless the alarm is confirmed by feeling the detectors together, in order to ignore the false alarm and prevent the release of gas without justification. |

|

| Given the use of one gas collector for each two adjacent rooms, we must provide the design with an automatic valve that takes its orders from the control panel, so that it remains closed and opens only in the direction that diverts the gas to the room in which the fire occurred only without the other room. |

|

| The design is provided with two manual pistons, one for canceling the alarm and the other for the immediate operation of the extinguishing system, in order to increase the effectiveness and speed of the system and to avoid false alarms. In addition to an alarm horn with a medium sound intensity (45 decibels) in order to alert workers of the presence of a fire in the room. [7] |

|

| 7-4- Design of the extinguishing system in the secondary sterilization section: |

|

| Due to the somewhat complex design of this section, as it is divided into five adjacent spaces, an automatic CO2 gas extinguishing system was not adopted, but it was provided with five manual extinguishers containing dioxide gas, so that they were distributed within all the voids of the space, and the fire can be extinguished with gas without That the extinguishing agent cause contamination of the place or disable the device. |

|

| 7-5- Designing the extinguishing system in the remaining spaces of the section: |

|

| A manual extinguishing system was relied upon, by using 13 hand extinguishers containing dry powder placed in the corridors and in open, easily accessible places. Extinguishers were placed based on the architectural design of the department and the standard distances between the extinguishers as mentioned in Chapter Five. |

|

| Figure (13) shows the final design of the extinguishing system. |

|

.png) |

|

| Figure (13): The final design of the extinguishing system for the Operations Department - Al-Basil Al-Qardaha Hospital |

|

| We note from the previous figure (13) that the automatic extinguishing system includes all operating rooms, so that one gas collector was used for each two adjacent rooms so that it contains the necessary cylinders for the larger room, and this collector was placed in addition to the control panel in the dirty corridor, which saves space and extensions and facilitates operations Periodic maintenance and inspection. |

|

| |

|

| 7-6 Examination and testing of the designed extinguishing system: |

|

| With regard to examining and testing extinguishing systems, the following matters must be taken into account: [1] |

|

| *All systems must be checked and tested at least once a year. |

|

| *The examination report must be filled out and the recommendations clarified in the presence of the person in charge or his representative. |

|

| *The amount of clean medium and the pressure of the cylinders must be checked. |

|

| *If it appears that the amount of clean media in the cylinder has decreased by more than 5%, or that there is a loss of pressure (adjusted according to temperature) by more than 10%, these cylinders must be refilled or replaced. |

|

| *Testing of cylinders: Clean media cylinders must not be refilled before being re-examined if a period of more than 5 years has passed since the date of the last examination, testing and inspection of these cylinders. It is allowed to be re-examined so that the test consists of a visual inspection as described in the manufacturer's instructions. |

|

| *Piping Test: All piping of the system shall be tested every 5 years, at a pressure value of one and a half times the maximum cylinder pressure. |

|

| The automatic extinguishing systems in the area to be protected must be checked and tested to ensure the effectiveness of their position and the extent of their tightness, in order to close any air leakage that causes the required concentration level of the clean medium not to be maintained for the specified period in the area to be protected. The preferred method of inspection is the use of air blower and smoke diagrams. The exact amount of clean media concentration and the specified period of protection shall be obtained as specified in the design. |

|

|

The area to be protected shall be checked at least once every 12 months to ensure that there are no holes or other changes affecting the leakage of the clean medium or a change in the size of the hazard. And when the inspection process indicates that there are conditions that lead to the inability to maintain the concentration of the clean medium, it must be corrected, and the area to be protected must be re-tested if there is doubt about that to ensure the effectiveness of the extinguishing system applied in it. [1]

|

|

| 8. The results of the study: |

|

| *The impact of the architectural design appears clearly in the design of the department's firefighting systems, and this design contributed to two different aspects: a positive aspect in terms of the direct adjoining of each two operating rooms, which facilitated the design and reduced the number of cylinders, tubes and connections required for the design, and a negative aspect in terms of the large areas of the operating rooms.(exceeding the standard ratios), which increases the volume of gas required for extinguishing. In addition to the design of the secondary sterilization section, which contains a lot of separators, which prevented us from designing an automatic extinguishing system for it. |

|

| *After examining the current reality of the Operations Department, it became clear how much the firefighting system was neglected, despite the seriousness of this department. |

|

| *The extinguishing systems used in the hospital are simple manual extinguishing systems limited to some wall extinguishers in most departments. |

|

| *There is often no diversity in operating room spaces within one wing, but most of the rooms have the same area as in our studied case. |

|

| *There are no procedures to limit the spread of fire in the department. |

|

| *Lack of awareness among workers in operations departments about the importance of safety and ways to act in the event of a fire. |

|

| *Designing an effective automatic fire extinguishing system that ensures safety for the patient, medical staff and equipment. |

|

| 9. Proposals: |

|

| *Taking into account the design of alarm and firefighting systems from the early stages of designing the hospital. |

|

| *Taking into account the geometric shape of the sections to achieve the best effectiveness of the extinguishing system. |

|

| *Full compliance with the teachings of the international standard for the extinguishing system. |

|

| *Avoid installing false ceilings in operating rooms as much as possible. |

|

| *Diversity of detectors when designing alarm systems. |

|

| *Adopting architectural designs in which the dirty corridor surrounds the operating rooms |

|

| *Emphasis on the periodic inspection and maintenance of the elements of alarm and firefighting systems. |

|

| 10. Future prospects: |

|

| *Using modeling, simulation and specialized computer programs when developing architectural designs |

|

| *Theoretical study of the occurrence of spark and spread of fire in addition to the density of thermal loads. |

|

| *Expanding the scope of the study to include a larger number of operations departments or other departments of hospitals. |

|

| *Making an architectural modification to the studied designs in order to improve them in terms of warning and extinguishing |

|

| |

|

| 11. References |

|

| [1] حمد,غسان (2009)," الشامل في الحماية من الحرائق", الطبعة الثانية, المملكة العربية السعودية. |

|

| [2] Medical Device Safety (MDSR) (1995) “Fires from oxygen use during Headand Neck Surgery “ECRI Institute, Hazard (Health Devices 24 (4):155-6). |

|

| [3] The Joint Commission (2003) "preventing surgical fires" Sentinel Event Alert, Issue 29. |

|

| [4] Rosen.M, Lee.B, Sampson.J, Koka.R, Chima.A, Ogbugu.O, Marx.M, Kamara.T, Koroma.M, Jackson.E, (2014) “Failure mode and effects analysis applied to the maintenance and repair of anesthetic equipment in an austere medical environment” International Journal for Quality in Health Care, Volume26, Number 4: pp. 404–410. |

|

| [5] Stephanie Joseph (2012), “Safety surveillance of medical device-related surgical fires “M.P.H., Emory University. |

|

| [6]القباعي,تامر (2006), "مقدمة في انظمة الاطفاء التلقائية واليدوية", عمان, الاردن. |

|

| [7] Kidde Fire Systems (2004),"FM 200®: ECS Series Engineered FireSuppression Systems", Design, Installation, Operation and Maintenance Manual,USA. |

|

|

[8]مخيبر,حنان (2014) " هندسة المستشفيات " المركز العربي للتعريب والترجمة والتأليف والنشر.

|

|